Why Choose MEMS Over Geophones for Smarter Highway Monitoring

A7 highway vibration monitoring:

time savings and reliability thanks to MEMS technology

Risk24 is part of the SP Group and takes care of all risk management and environmental monitoring activities for structural and civil engineering works.

WhatMonitoring construction activities at major highway.

A7 highway near the Munnikesloot.

Contractor Macadam is building a new bicycle bridge next to the existing A7 highway bridge near the Munnikesloot. Vibration monitors are being installed to monitor the impact of these construction activities on the A7 bridge. This is a critical task because vibrations that could potentially compromise the integrity of the existing structure may be generated during the construction of the bicycle bridge, for example, during piling operations.

The vibration monitors are mounted on the piers standing in the water. This is normally a tricky and time-consuming task, especially when working from a boat with vibration monitors that use geophone technology. With geophones, it's crucial that they are mounted exactly level and securely. If a geophone-based vibration monitor isn't perfectly level, it provides inaccurate and typically lower readings.

However, RISK24 has been using Omnidots SWARM Vibration monitors with MEMS technology for quite some time. Thanks to this digital technology, mounting them on the bridge piers was a breeze. The SWARM vibration monitors could simply be screwed on after drilling a hole in the pier, with no alignment needed.

This is due to two key advantages of the Omnidots SWARM Vibration monitors:

- Automatic Alignment: The sensors automatically ensure correctly aligned axes.

- MEMS Technology: Because MEMS sensors are insensitive to mounting orientation, they always provide reliable measurements, regardless of how they are attached.

This technology made the mounting process fast and hassle-free, without worrying about crooked sensors or inaccurate measurements.

Benefits of working with Omnidots' solution

Easy

The Honeycomb portal is remarkably easy to use. The daily reports are of excellent quality, and the project settings are straightforward.

Effective

Products used by

Risk24

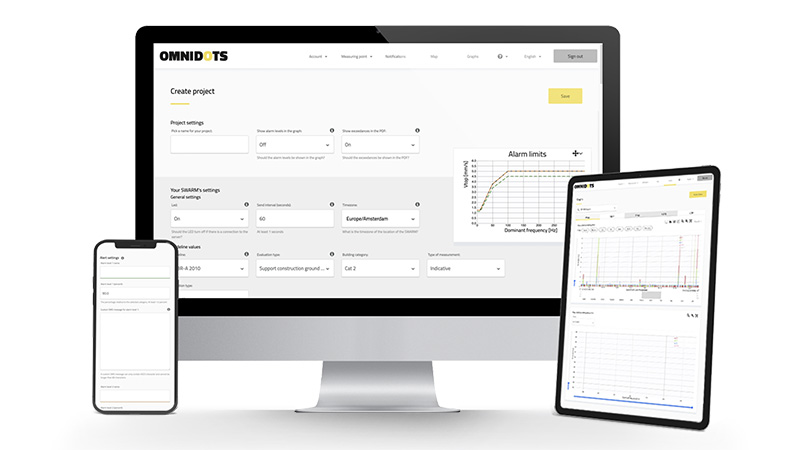

Honeycomb Cloud software

Realtime monitoring, analyzing and reporting SaaS solution.

SWARM Vibration monitor

Stay ahead of damage—real-time, effortless vibration monitoring.

SWARM Battery

Up to six weeks of monitoring on one battery charge.

Any questions? Reach out to sales expert Jurjen!

When it comes to understanding our solution and how it perfectly suits your needs, Jurjen is the person you should reach out to.