What measuring equipment is needed for DIN4150-3 and DIN4150-2?

Vibrations can be a source of annoyance or damage if they exceed certain values. With the right measuring equipment, you will always know whether you are staying within the norms and standards that the DIN4150-3 (damage to buildings) and DIN4150-2 (the influence of vibrations on people in buildings) regulations prescribe.

But what equipment do you need for accurate DIN4150 measurements?

A brief history of vibration measurement systems

It is useful to look back in time to understand current measuring equipment better. In 1988, performing a vibration measurement was a physically demanding job. Your kit consisted of a vibration measurement system with separate accelerometers and a drag-and-drop Compaq computer. In that computer was a Bakker card (by the firm Bakker). In addition to the accelerometers and the computer, you also had to carry a heavy generator.

With this system, it was possible to measure very little, precisely four seconds. Then came the task of recording and saving the data and finally drawing it out back at the work office with a pen plotter. In the end, you could only put one point on the graph, in contrast to present times when it is possible to place thousands of points on a graph. A lot more was possible with the IFCO VM measuring system introduced in 1992. Here, the use of a generator was no longer needed. The IFCO VM measuring system used batteries that could last up to three weeks. In addition, the system had three geophones, and it was possible to take measurements in three different directions.

Major steps were again taken in 2004 with the arrival of the Axilog (3D geophone and the first measuring device with a modem for remote access) and the introduction of the Redbox in the Netherlands. A year later, an important update of the IFCO system followed. The Profound Vibra-SBR operated on both batteries and mains power and was also equipped with a SIM card. This was followed by upgrades of the Redbox in 2014 and the Axilog (the rechargeable Axilog II). From 2018, the advancement in vibration meters would follow each other in rapid succession. This resulted in increasingly compact devices (in some cases, no bigger than a matchbox) with creative names such as SWARM, Spyder, and Frogwatch. To match the curve of modern times, fewer device buttons and more useful features appeared to fit everyone's needs.

The measuring equipment

Vibration measurement technology has evolved steadily towards compactness and greater ease of use. But which measuring equipment is needed in modern times to perform a good DIN4150-2 or DIN4150-3 measurement?

The vibration monitor

The whole process of measuring begins with a quality vibration meter. Would you like to ensure you have the proper meter for DIN4150-3 or DIN4150-2? Please pay attention to the points of attention below.

The frequency range

When choosing a vibration meter for SBR-A or SBR-B measurements, the frequency range is the first consideration. A measuring device for SBR-B should have a slightly different frequency range (1-80 Hz versus 1-100 Hz for SBR-A) and a significantly larger dynamic measuring range (measured in the quantities of acceleration, speed, or displacement) than a vibration meter for SBR -A. A system for SBR-B must measure approximately ten times more accurately than an SBR-A system.

Filtering low frequencies

Another specific requirement for the measuring equipment has to do with frequencies on the two extreme sides of the vibration spectrum. A measuring device must be able to filter low frequencies below 1 Hz (long wavelengths) from the vibration spectrum. This can easily be compared to filtering sand, where you first sieve out the coarsest grains. In addition, you also want to filter out the very high frequencies. You can filter them out with a high-pass filter. The range between 1 and 80 Hz remains exactly the range the device must accurately measure.

Battery and charger

Do you measure in a place where you do not have access to mains power? Of course, you would want to ensure that your vibration meter does not stop measuring halfway through the project. Fortunately, battery technology has made great strides in recent years. Nowadays, batteries can be used for six weeks without having to recharge them in between periods. Due to the robust design, many models are also resistant to heat, cold, dust, and sudden shower.

Suppose the battery for your device is becoming dangerously low while in the middle of measuring a project. It is possible to charge the device while it is still in use. With the Omnidots solar panel, you can charge your battery and continue to measure at the same time. A Power over Ethernet adapter completes the package and allows you to supply power via the Ethernet cabling. This is handy when measuring in a cellar or tunnel with no 3G / 4G/ LTE, WiFi, or mains power.

Analysis tools

Your vibration meter has done its job properly. You now have access to your measurement data, which gives you insight into the possible vibration nuisances caused by a construction project or the continuously moving freight traffic at an investigated location. But then, of course, you are not entirely finished. You also need software and a platform to analyze, group, filter, and interpret your measurement data.

With a modern and versatile platform such as Honeycomb (SWARM), Vista Data Vision (Profound VIBRA), or THOR (Instantel Micromate), performing a DIN4150 or SBR measurement becomes a lot easier and more fun.

- A cloud platform can be reached from any location on your tablet, laptop, or smartphone. This is handy if you want to upload or view your measurement data at any location and even on your way home.

- You can configure the settings of your vibration meter via the platform. Honeycomb, for example, is the platform where you can set your SWARM and preferences (a versatile, sensitive, and user-friendly meter that you can use for both SBR-A / DIN4150-3 and SBR-B / DIN4150-2 measurements).

- Exporting measurement data to PDF, CSV, or Excel overviews becomes a breeze.

- You can send automatically generated reports daily or weekly to multiple recipients. This is possible with the Honeycomb platform.

- The status of your vibration meter, the battery level, or even the GPS location from where you are working; with the right platform, it can easily become a simple and transparent process. Are limit values being exceeded, or is the battery of your vibration meter on its last stretch of energy? You can customize the system to receive automatic notifications by e-mail or text message so that you can be aware of all moving parts.

- Can you immediately remember detailed measurements of specific projects carried out in a project from previous months? With the right software, you can archive measuring points.

- Detailed charts? With a good platform and the right software, you can create and display them instantly.

The right measuring equipment at Omnidots

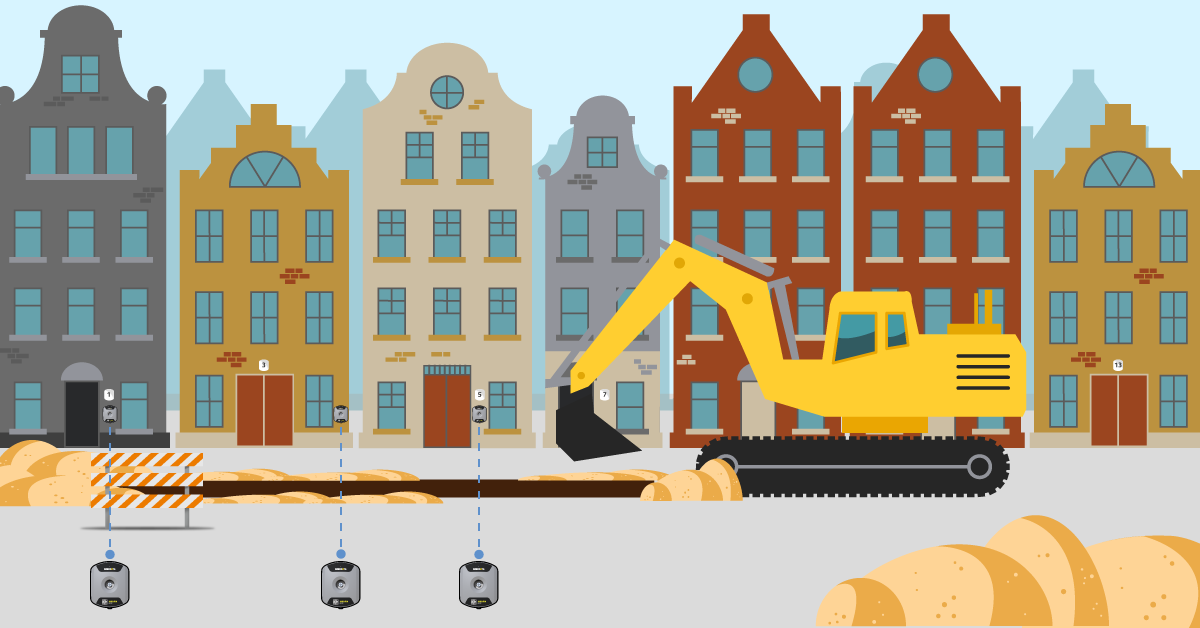

Are you looking for a high-quality, efficient, and reliable vibration measuring system for the SBR-A / DIN4150-3 and SBR-B / DIN4150-2 guidelines? You've come to the right place with Omnidots. The SWARM vibration meter, the Honeycomb web platform, and the SWARM battery all form the total solution for measuring vibrations in construction.

Share this

You May Also Like

These Related Stories

Why construction vibration monitoring is necessary for your project

When to use the Omnidots vibration monitoring and reporting solution